All the components used to manufacture the bulk bag are brought together. The gathered parts are assembled to form an FIBC or bulk bag by highly skilled and trained laborers under the supervision of technically qualified supervisors.

Akshar International one of the leading manufacturer and global supplier of a wide range of FIBC and PP bags like standard Fibc bags, 4 Panel bags, U Panel bags, Baffle bags, ventilated bags, one-two loop bags, Food &Pharma Grade Fibc bags, UN Certified, PP woven sacks, laminated-un laminated woven bags and woven fabrics.with range of packaging solutions like FIBC (Jumbo Bags) which are currently used in various industries including fertilizer, cement, sand, food grains, sugar, cattle feed, fish meal, pulses, spices, dates, agro products, minerals, resin, polymers, rubber, etc.

Industries Served

Our Process

SEWING

Our Process

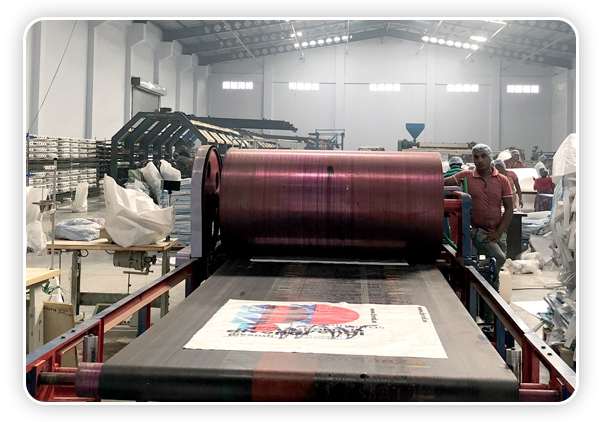

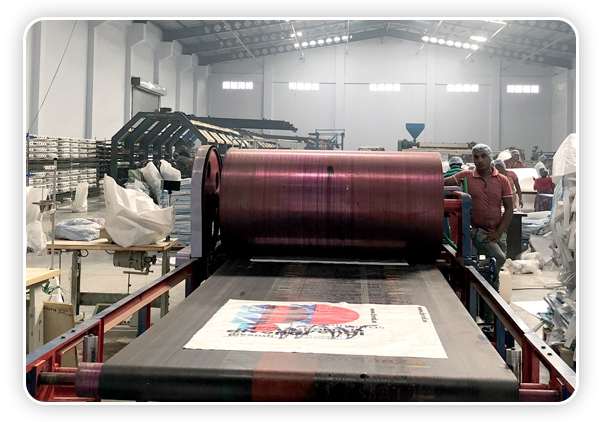

PRINTING

The body fabric panels are then fed into a printing machine to make a printing impression on the fabric.

Our Process

CUTTING

The fabric in rolls is run through an automatic cutting machine and is cut to a specific size. This automatic process is adopted to get better accuracy in cut size.

Our Process

LAMINATION / COATING

Polypropylene fabric is laminated with a semi-clear PP film that is bonded to the woven material to create a moisture barrier. This is an optional process as per the requirement of the custom.

Our Process

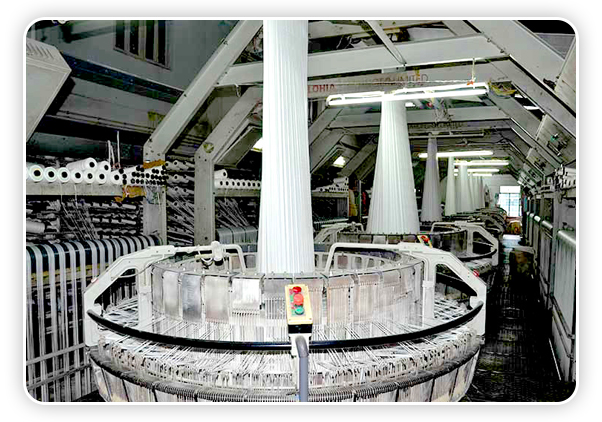

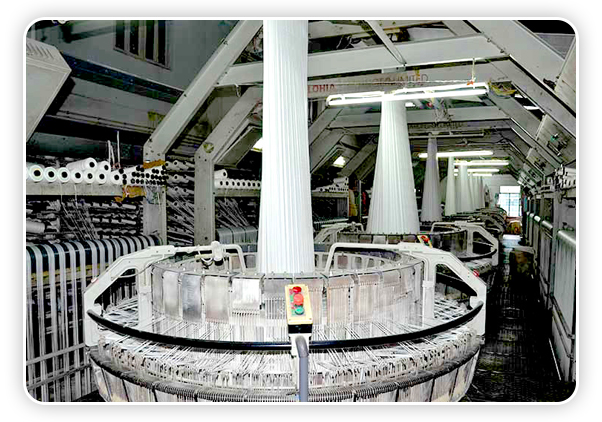

WEAVING

Extruded tape bobbins are loaded in the circular/tubular weaving loom or setup for the flat loom. Here the tapes will be woven into fabric of a required specification and size and will be wound in roll form. These woven fabrics are used not only for the body of the FIBC, but also the fill and discharge components.

Our Process

EXTRUSION

Here the mix of virgin polypropylene granules, ultra violet inhibitor, calcium carbonate, and sometimes color pigment are being melted and converted into tapes in an extrusion plant. At the end of the extrusion line these tapes are wound on bobbins of required a size. This is the first stage of process which determines the tensile strength of the tape

Our Process

SEWING

All the components used to manufacture the bulk bag are brought together. The gathered parts are assembled to form an FIBC or bulk bag by highly skilled and trained laborers under the supervision of technically qualified supervisors.

Our Process

PRINTING

The body fabric panels are then fed into a printing machine to make a printing impression on the fabric.

Our Process

CUTTING

The fabric in rolls is run through an automatic cutting machine and is cut to a specific size. This automatic process is adopted to get better accuracy in cut size.

Our Process

LAMINATION / COATING

Polypropylene fabric is laminated with a semi-clear PP film that is bonded to the woven material to create a moisture barrier. This is an optional process as per the requirement of the custom.

Our Process

WEAVING

Extruded tape bobbins are loaded in the circular/tubular weaving loom or setup for the flat loom. Here the tapes will be woven into fabric of a required specification and size and will be wound in roll form. These woven fabrics are used not only for the body of the FIBC, but also the fill and discharge components.

Our Process

EXTRUSION

Here the mix of virgin polypropylene granules, ultra violet inhibitor, calcium carbonate, and sometimes color pigment are being melted and converted into tapes in an extrusion plant. At the end of the extrusion line these tapes are wound on bobbins of required a size. This is the first stage of process which determines the tensile strength of the tape

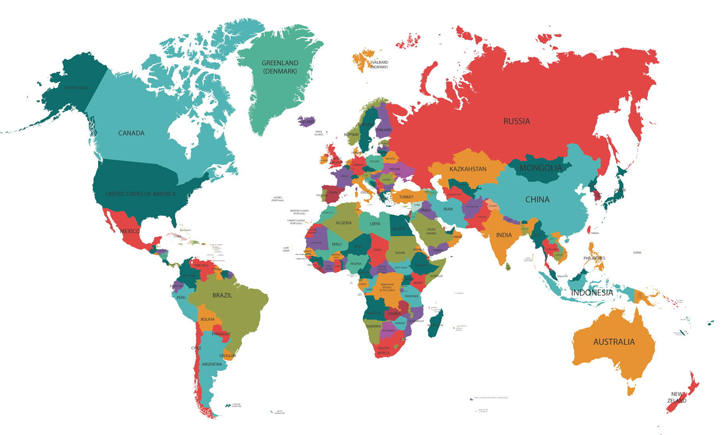

Global Footprints

Our integrated FIBC (Flexible intermediate Bulk Containers) facility allows us to create highly customized solutions to meet your needs. We presently serve more than 42 countries in the world. Our desire to make the highest quality food grade FIBCs available to you is taking us to new parts of the world every day.

In order to be the best FIBC bags Manufacturer, we have created a symphony between man, machine, and process. Best in class processes have been implemented. Our passion is to be the preferred product manufacturer for our clients each and every time.